Solidification Patterns in Metallic Systems

Salar Niknafs, Mark Reid, Rian Dippenaar, Dominic Phelan

School of Mechanical, Materials and Mechatronics Engineering,

Faculty of Engineering and Information Sciences,

University of Wollongong, Australia

Solidification patterns in crystalline systems are one the most aesthetically pleasing examples of pattern formation in nature. During solidification when a planar solid/liquid interface becomes unstable, it reorganizes itself into cellular and dendritic micro arrangements. These interfacial patterns appear as fractal features and their level of complexity is characterized by their fractal dimension or by their primary and secondary arms spacing. In metallic systems, because solidification microstructure is a defining link between production techniques and the mechanical properties, it is technologically crucial and economically favored to achieve desired properties of the final product through a controlled solidification process.

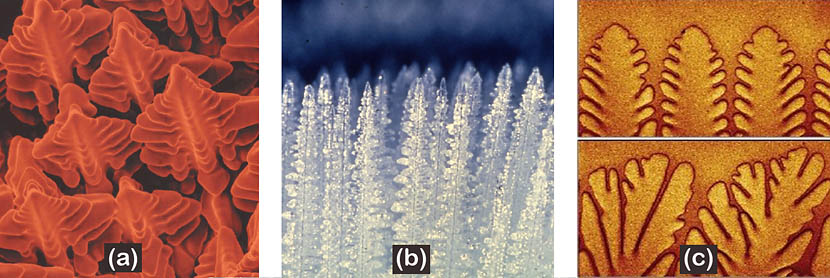

Figure 1.

Advancing dendrites in (a) a nickel-based superalloy (Photo by David, Babu, and Vitek - JOM 6/03), (b) crystallising ammonium chloride solution. (Photo by Mark Hallworth, courtesy of Grae Worster, University of Cambridge) and (c) succinonitrile/ethylene oxide, courtesy of Max Planck institute for dynamics and self-organization)

Advancing dendrites in (a) a nickel-based superalloy (Photo by David, Babu, and Vitek - JOM 6/03), (b) crystallising ammonium chloride solution. (Photo by Mark Hallworth, courtesy of Grae Worster, University of Cambridge) and (c) succinonitrile/ethylene oxide, courtesy of Max Planck institute for dynamics and self-organization)

A large number of research has been conducted to describe the solidification patterns in a multi-disciplinary field of materials sciences, physics, physical chemistry, mathematics and computational engineering. These diverse studies are collected in significant books of Dantzig and Rappaz [1] and Kurz and Fisher [2].

One of the major obstacles for the solidification studies in metallic systems is its occurrence at high temperatures and the lack of experimental techniques to observe this phenomenon in real-time. Hence all the previous in-situ research was carried out on substitute transparent materials, which mimic the forms of solidification in metallic systems. The real-time technologies and adequate techniques to observe patterning in metallic-systems-themselves were only introduced in the recent years eventually proving the possibility to answer the fundamental question: to what extend the substitute transparent materials can mimic the forms of solidification in metallic systems?

Our proposed study [3] uses a high-temperature Laser-Scanning Confocal Microscopy (LSCM) combined with in-house technological advancements to make real-time observations of phase transformations at high temperatures and such system was used to observe pattern formations during steel solidification. Concentric Solidification technique [4] was developed by creating microns-thick liquid pools in the center of disc-shaped specimens, surrounded by a solid rim, as depicted schematically in Figure 2.

One of the major obstacles for the solidification studies in metallic systems is its occurrence at high temperatures and the lack of experimental techniques to observe this phenomenon in real-time. Hence all the previous in-situ research was carried out on substitute transparent materials, which mimic the forms of solidification in metallic systems. The real-time technologies and adequate techniques to observe patterning in metallic-systems-themselves were only introduced in the recent years eventually proving the possibility to answer the fundamental question: to what extend the substitute transparent materials can mimic the forms of solidification in metallic systems?

Our proposed study [3] uses a high-temperature Laser-Scanning Confocal Microscopy (LSCM) combined with in-house technological advancements to make real-time observations of phase transformations at high temperatures and such system was used to observe pattern formations during steel solidification. Concentric Solidification technique [4] was developed by creating microns-thick liquid pools in the center of disc-shaped specimens, surrounded by a solid rim, as depicted schematically in Figure 2.

Figure 2.

Schematic representation of the concentric solidification technique where a liquid pool is produced, surrounded by delta-ferrite rim in a steel sample and the onset of planar to cellular transition observed in-situ and in real-time in a high-temperature laser-scanning confocal microscopy. Images by of Salar Niknafs, courtesy of The University of Wollongong.

The main justification for this technique is that the surface tension balance between solid, liquid, gas and crucible results in a stretched liquid region with significantly reduced meniscus effect. Consequently, the area at which the solid/liquid interface can be observed enlarged and the quality of the images significantly enhanced.

Using the Concentric Solidification technique, pattern formations during solidification of steel were observed in real-time and subsequently the effect of cooling rate and alloy composition on the cellular spacing were discussed morphologically and analytically. A series of experiments were carried out at cooling rates that varied between 5K/min to 2500K/min. Within this range of cooling the planar interface developed a perturbation wave, which eventually developed into cells and/or dendrites, while a He-Ne laser system scanned the surface and captured the events as real-time videos. Video 1 shows the onset of planar to cellular transition in a low-carbon steel, cooled at a rate of 5K/min.

Using the Concentric Solidification technique, pattern formations during solidification of steel were observed in real-time and subsequently the effect of cooling rate and alloy composition on the cellular spacing were discussed morphologically and analytically. A series of experiments were carried out at cooling rates that varied between 5K/min to 2500K/min. Within this range of cooling the planar interface developed a perturbation wave, which eventually developed into cells and/or dendrites, while a He-Ne laser system scanned the surface and captured the events as real-time videos. Video 1 shows the onset of planar to cellular transition in a low-carbon steel, cooled at a rate of 5K/min.

Video 1.

Onset of planar to cellular transition of the solid/liquid interface, observed in-situ and at temperature in a laser-scanning confocal microscopy. Sample is a low-carbon steel, cooled at a rate of 5K/min.

References

- Dantzig, J. A., Rappaz, M. “Solidification: Methods, Microstructure and Modelling”. EFPL Press; 1 edition (2009).

- Kurz, W., Fisher, D. J. “Fundamentals of Solidification”, Enfield Publishing & Distribution Company; 4th edition (1998).

- Niknafs, S., Phelan, D. and Dippenaar, R.: “High-temperature laser-scanning confocal microscopy as a tool to study the interface instability during unsteady-state solidification of low-carbon steel”, Journal of Microscopy, 249(2013), p. 53

- Reid, M., Phelan, D. and Dippenaar, R.: “Concentric solidification for high temperature laser scanning confocal microscopy”. ISIJ International, 44(2004), p. 565

© Salar Niknafs 2024, All rights reserved

All elements of this site, including the images and text content, audio clips and videos are protected by International Copyright Law. Material published here may not be reproduced in any format without the express written permission from Salar Niknafs.